|

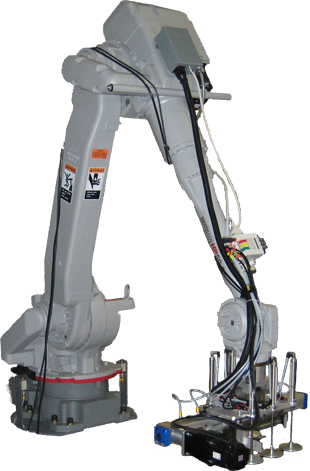

This was a project I worked with at Production Robotics in San Leandro. This is a 6 axis robot, primarily used as a De-Palletizing robot. The overall automation system consisted of an "Assembler" an "Edge Dyer" a "Palletizer" a " De-Palletizer and an entire Conveyer system to link all the machines. I interfaced these robots with touch screen user interfaces, PLC Cabinets, and various servo systems to feed from conveyers as well as end This is by far one of my biggest most complex, projects to date.

Content coming soon: |

||

|

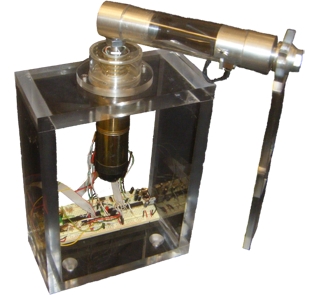

Hezekiel and I fabricated this entire thing from scratch in about 8 weeks. Working 20 hour days, was not uncommon and sleeping at school in the senior project room became a state of normality. Lesson learned, "life is a blur" especially without sleep. Everything was custom made, on mills, lathes, presses and saws. All the circuits were designed from scratch, no H-bridge motor driver here, just FETs and Opto-isolators with dual 20MHz MCU control. The software for the MCU's were developed in C and the GUI application to manipulate the PID controller and plot the real-time position were coded with MATLAB. Check out the Inverted Pendulum Page page. |

||

|

This is a project that was brought to me by my step brother, who had a need for Anti-lock Brakes on his trailer. He lives in the Boulder Creek and tows frequently. Him and I worked to fabricate the jig to test my design. This project incorporates an accelerometer to sense the deceleration of the vehicle and apply proportional braking force. It also has a feedback sensor which provides data for the current state of the wheel frequency, which is needed to determine if the brakes have locked up. The prototype phase of this project is thoroughly described in the write-up. All of the design considerations and constraints are laid out in the methods section of the report Check out the Write-up |

||

|

This is a project from high school that I worked on for many many years. This car started as a rusty, primed, stock piece of work, politely put. I knew I wanted more horse power, but when I opened the Summit order catalog it was all over. My step dad and brothers were integral in helping me fabricate this monster. It is fully "Back-halved", tubbed with ladder bar/coil over suspension. 4 wheel disc brakes, 2 inch drop spindles, 12 point roll cage, 18 inch wide tires, 3 inch 'X' pipe exhaust, and 600+ ponies under the sole of the foot. Like I said it is a MONSTER! It runs 10.80s @ 124 mph and it is street legal. Here's a brief showcase |

||